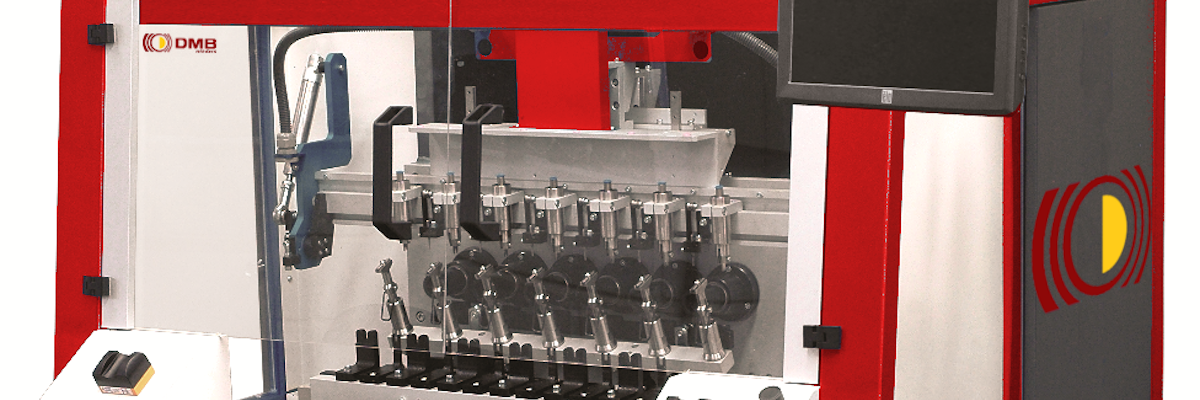

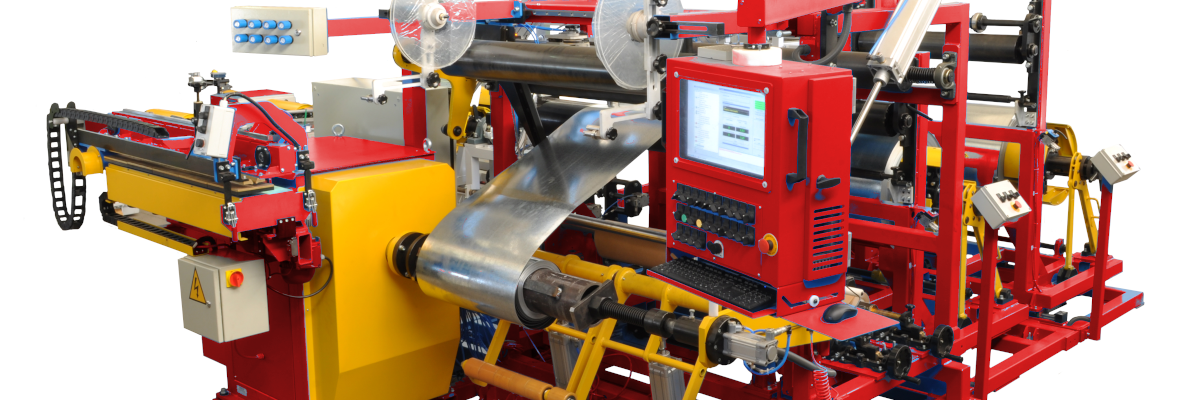

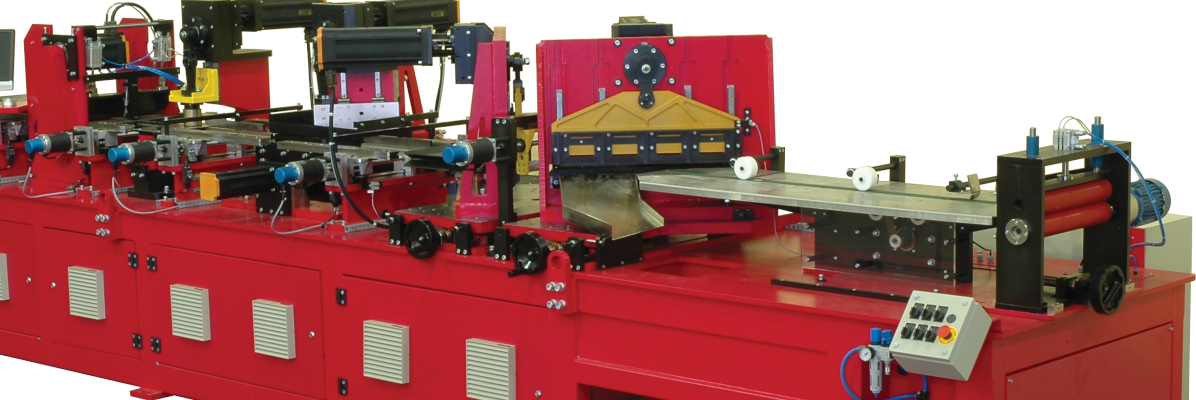

In this coil winder, the bobbin is vertically fixed on a rotating base and kept in place by a tailstock. The wire unwinding system is placed on an elevation platform that works together with the machine’s wire guides.

This vertical coil winding machine has a wire guide traverse for aluminum/copper wires.

The platform with the unwinding system can be manually controlled by the operator or programmed to move along with the winder.

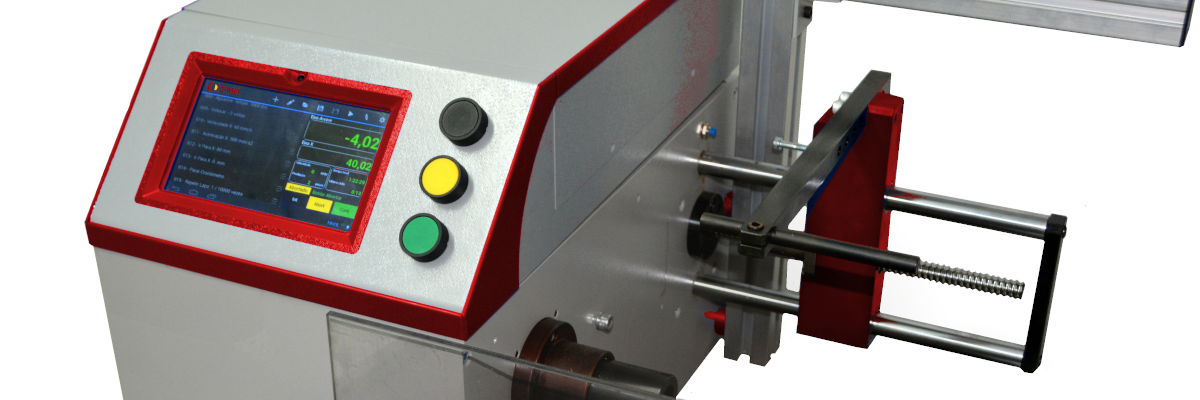

| HMI | Touch screen with Windows PC or Android Tablet |

| Spindle Motor | AC Motor with 15 or 25 HP |

| Spindle Max Speed | 25 rpm |

| Traverse Motor | Brushless Servo |

| Traverse Max Speed | 10" (250) in/s (mm/s) |

| Traverse Pitch | From 0.02" (0.5mm) to 20" (500mm) / revolution in (mm) |

| Traverse Travel | 185" (4700) in (mm) |

| Max Coil Diameter | 197" (5000) in (mm) |

| Tailstock Max Distance | 197" (5000) in (mm) |

| Platform Span | from 250" (1000) to 138"(3500) in (mm) |

| Platform Speed | up to 20" (500) in/min (mm/min) |

| Power Supply | 3x220 3x380 or 3x440 with ground V |