This machine is custom made to your needs.

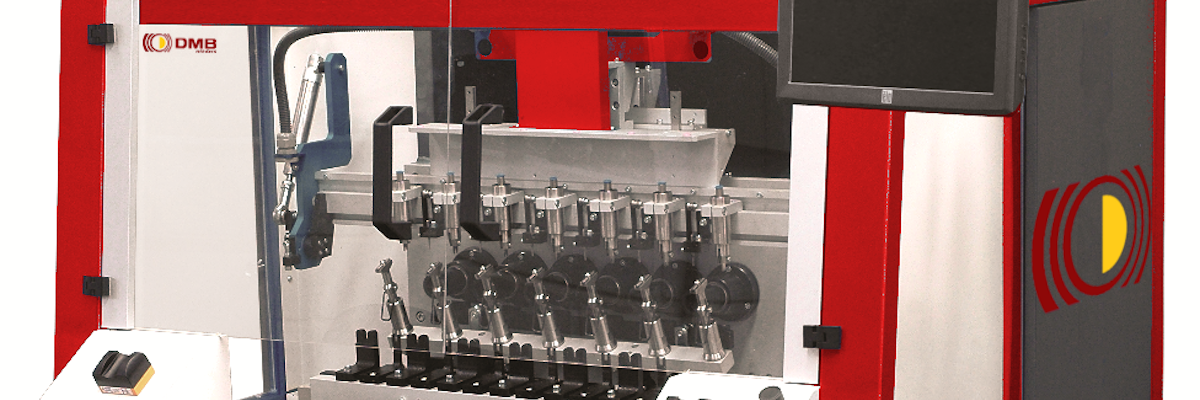

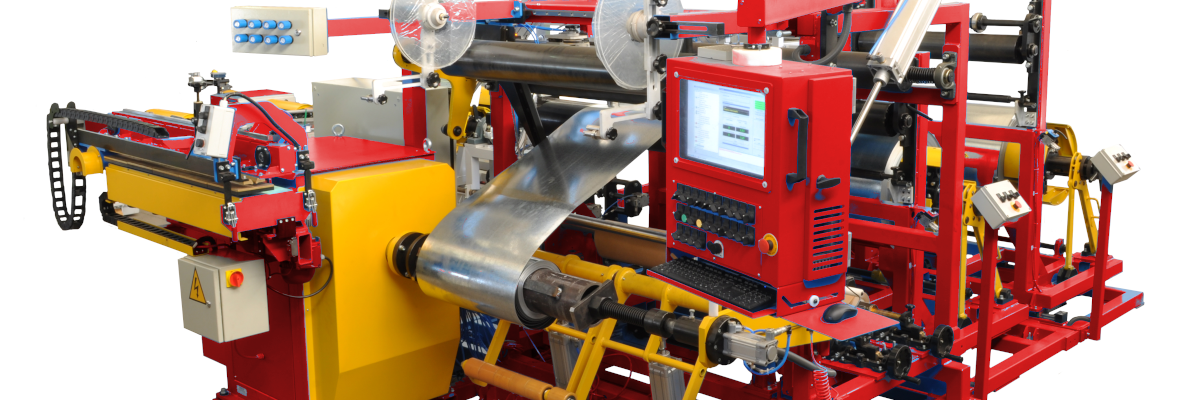

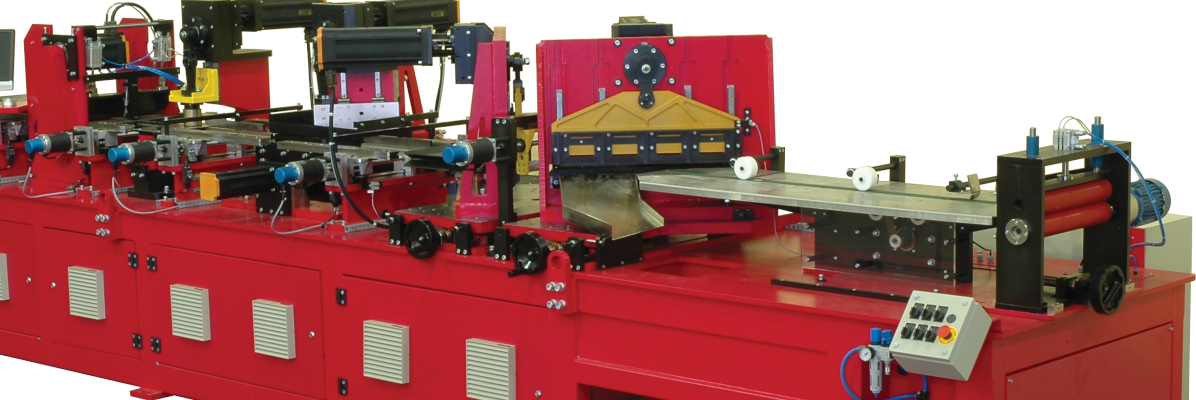

This equipment has a vertical recirculating system, which is able to operate with up to 30 armatures loaded in the magazine. The machine operation is done in four stations: Load and unload, heating, varnish application and resin cure.

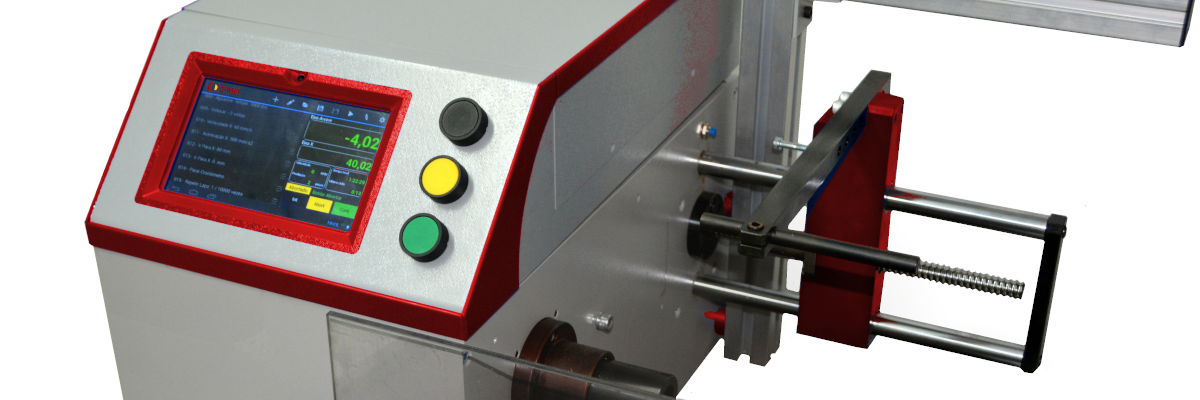

It has control of parameters such as: cure temperature; armature circulation speed, armature rotation; and varnish pump output in every head.

The armature might be loaded and unloaded manually or automatically by a manipulator. The fixation of the armature to the circulating system is possible due to spring closing nippers. Allows to operate with different diameter shafts.

The equipment is provided with a venting system for the varnish and resin volatile vapors and tank level control.

The load and unload station is in the lowest point of the circulating system trajectory. After being loaded the armature move up receiving heat in the heating station while they are monitored by infra-red thermal sensors. On the top of the system the varnish is applied to the armature by tubes connected to peristaltic pumps. The heating process keeps on during the descent (return) always being monitored by infra-red thermal sensors. During the whole process, the armatures spins on its own axis. The circulating system stops for an instant to allow the load and unload of each armature.