Small affordable coil winding machine for low production, with powerful control and remote access capability.

| SKU: | L1 |

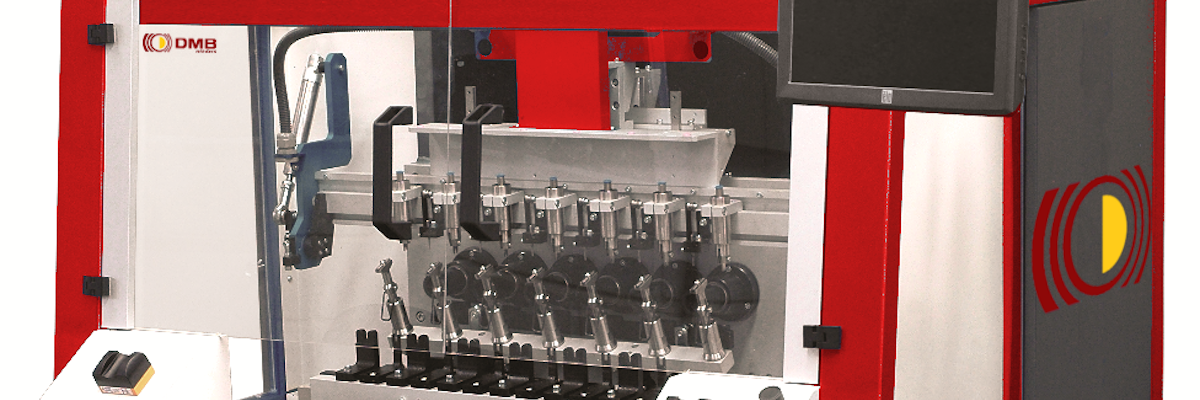

This machine allows the execution of a wide range of simple or complex coils. It has a simple and flexible CNC control added to a strong and accurate mechanics.

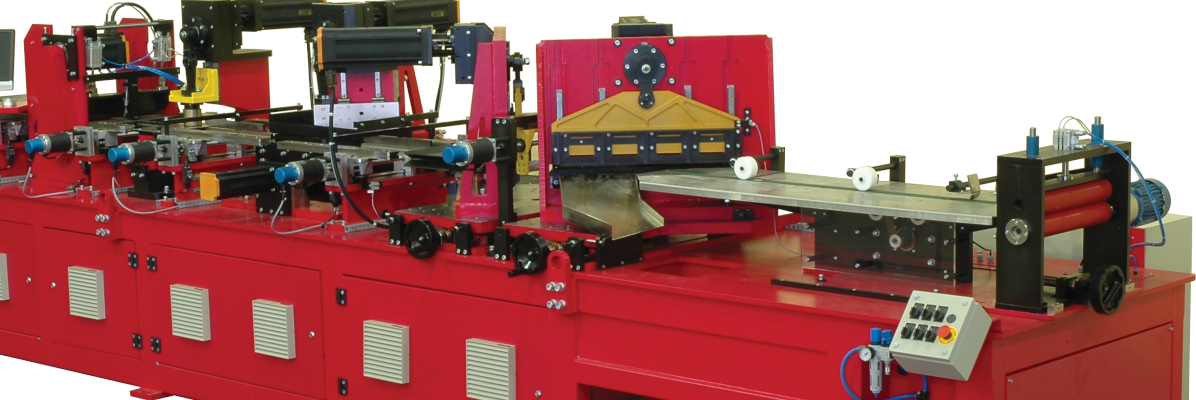

Lateral operation of this model is a highly productive alternative for coils where an extensive manpower is required. Machine executes coils of extreme characteristics with diameters from 0.2 up to 180 mm and wire gauges from 44 (0.05 mm) up to 10 AWG (2.5 mm).

This equipment is ideal for companies requiring a quick setup in medium to small production volumes.

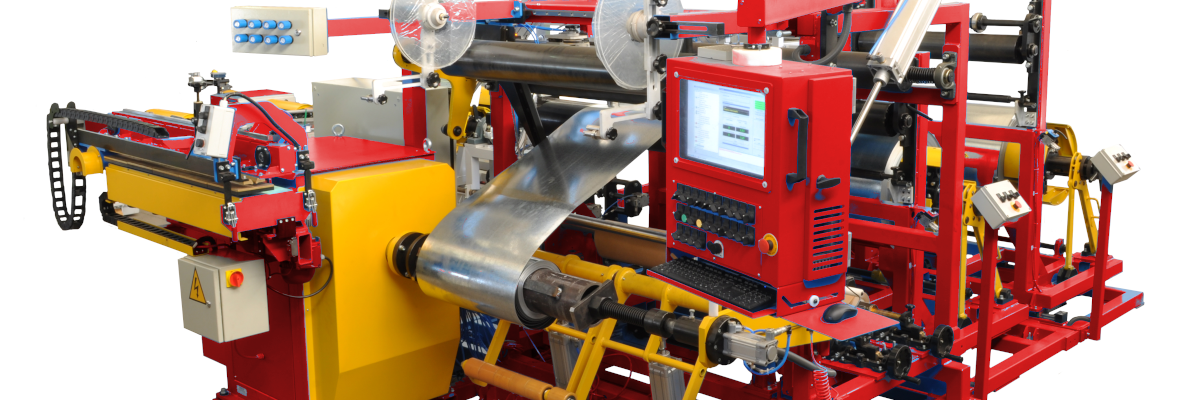

Transformers, switch power supply transformers, ballasts; air core coils, inductors, ignition coils, fly back transformers, loudspeakers, etc.

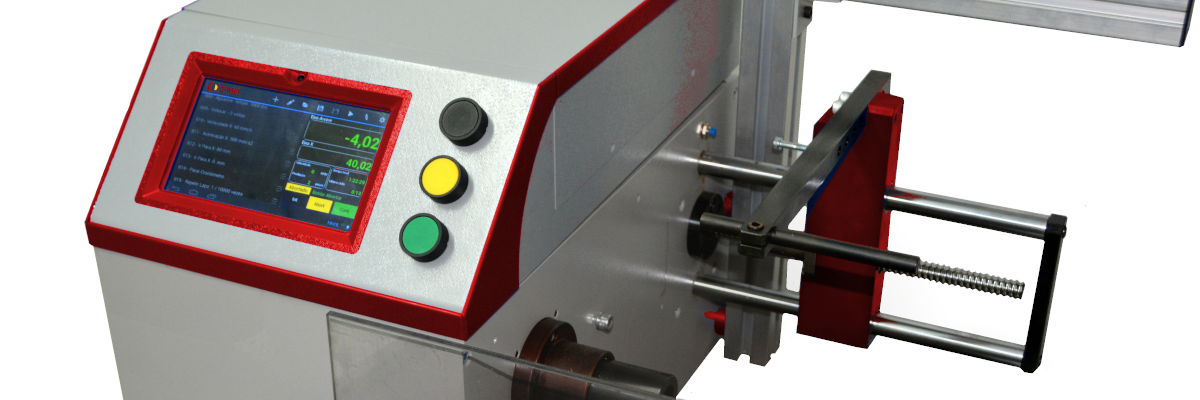

| HMI | Touch screen with Android Tablet |

| Spindle Motor | AC Motor or Brushless Servo |

| Spindle Max Speed | 6,000 or 10,000 rpm |

| Traverse Motor | Stepper Motor or Brushless Servo |

| Traverse Max Speed | 4" (100) Stepper option up to 16" (400) Servo option in/s (mm/s) |

| Traverse Travel | 4,7" (120) in (mm) |

| Max Coil Diameter | up to 7" (180) in (mm) |

| Wire | up to 10 AWG (2.5) (mm) |

| Power Supply | 220 with Grounding V |

| Weight | 176 (80) lbs (Kg) |

| Dimensions | 24" x 32" x 20" (600 x 800 x 500) in (mm) |