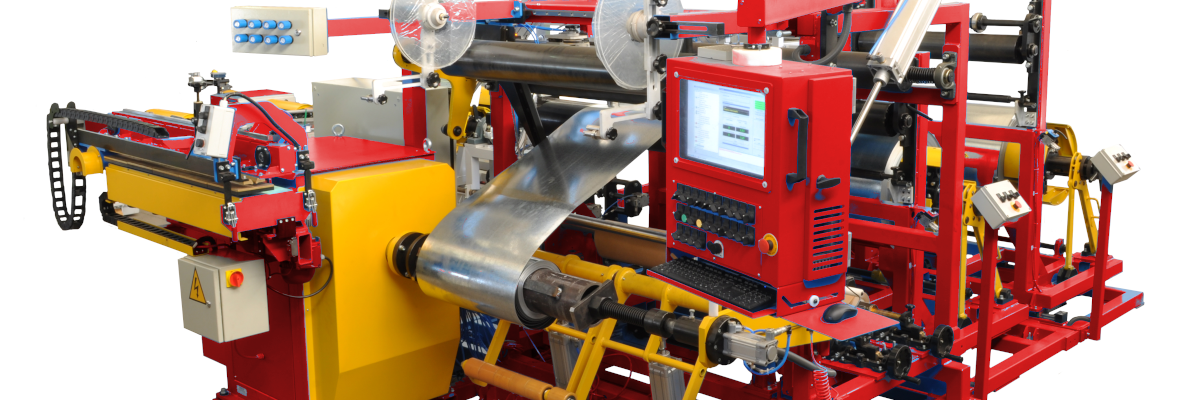

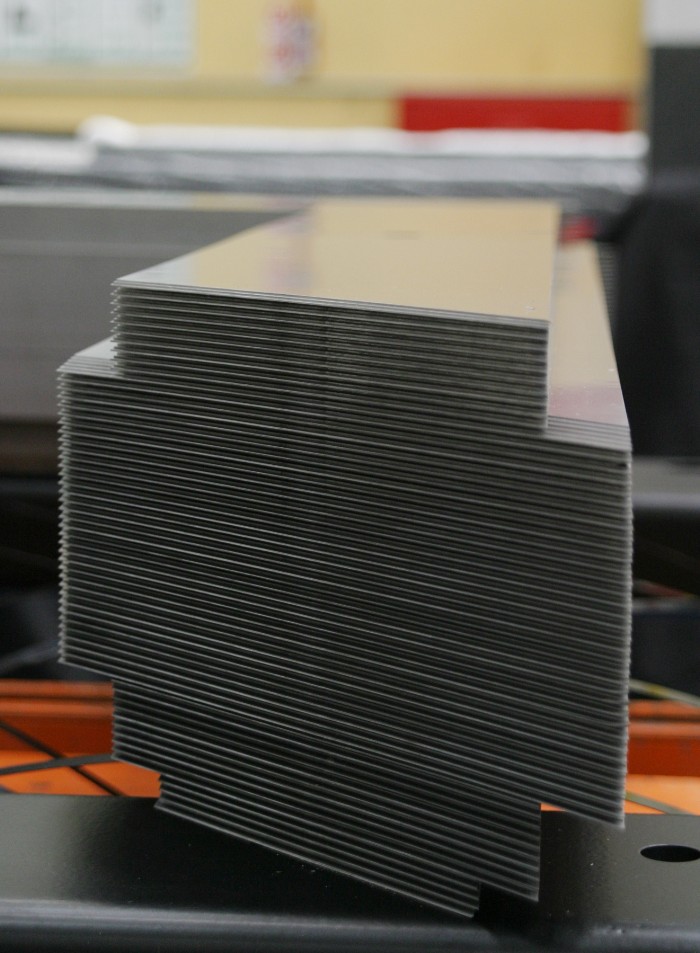

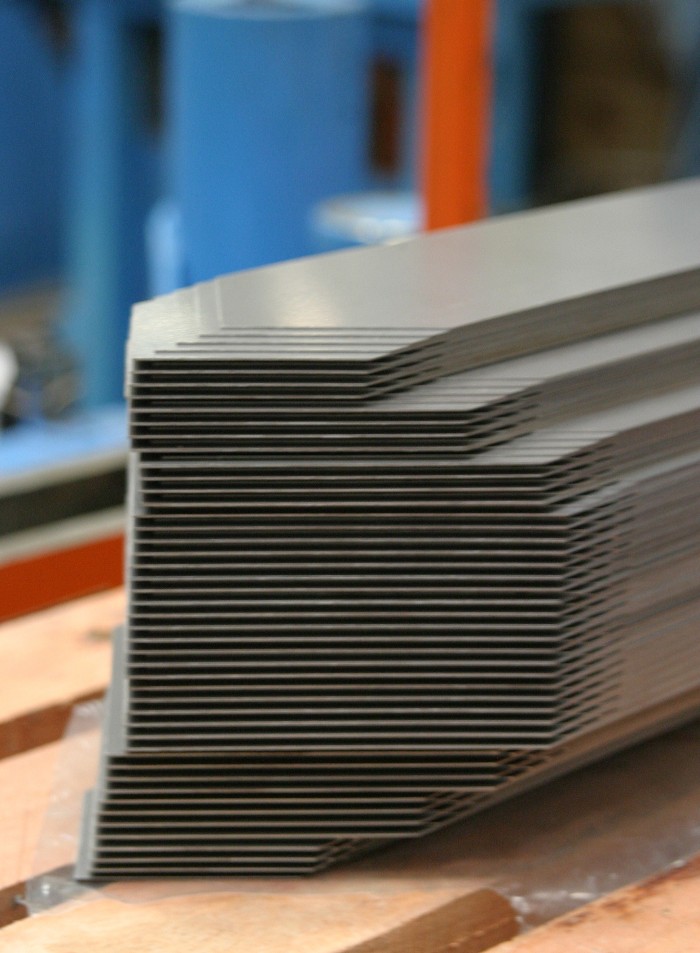

The C40 core cutting line has been designed to cut silicon steel strips for transformer cores from 40 to 400 mm width, maximum length of 2000mm and maximum thickness of 0,35mm. A decoiler feeds the machine synchronized to the roller-feeding unit. The feed unit controls the strip position precisely of the hole-guide, “V-Notch”, shears, producing sheets in an appropriate sequence to mount the transformer core. The roller-feeding unit, the hole-guide punch all the shears and al strip guides are driven by servo motors (no hydraulic system) and all driven and digital read-out is done via CAN BUS.

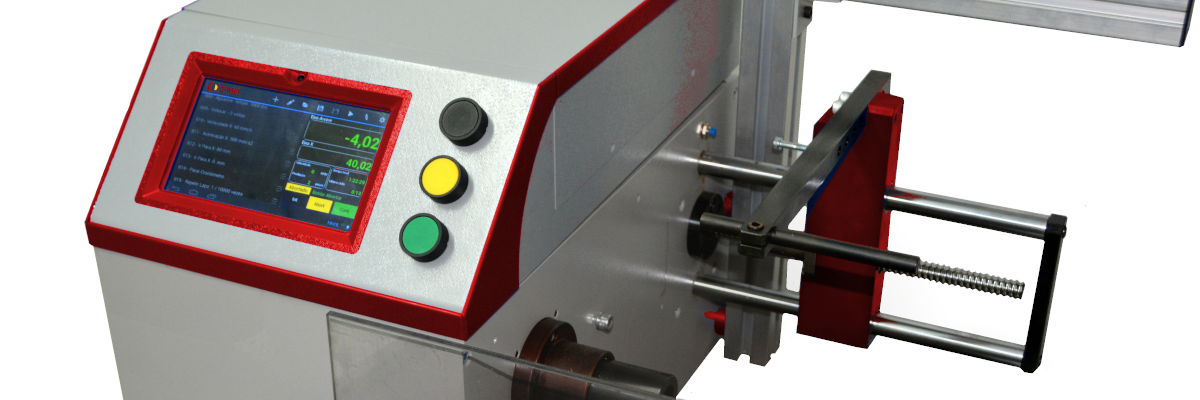

| Programming | The machine command works on Windows interface doing easier the interaction of the machine with the operator and the programmer. By a simple and versatile programme is possible to program a cut sequence or using the “Step Lap” system for a complete transform core assembling. The programs are archived into an Industrial Computer hard disk or other media system like CD. |

| Decoiler |  The decoiler has two expandable mandrels with capacity to carry two tons (each one ). It expands from 400 to 600 mm. The decoiler has two expandable mandrels with capacity to carry two tons (each one ). It expands from 400 to 600 mm. |

| Guidance System |  The sheet guidance has positioning individuals motors. So set up and offset procedures are easy and fast. The sheet guidance has positioning individuals motors. So set up and offset procedures are easy and fast. |

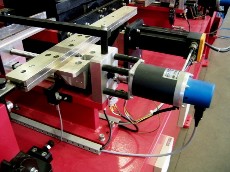

| Roller-feeding System |  The Roller-feeding System is driven by a servo motor that guarantees precision and speed. The Roller-feeding System is driven by a servo motor that guarantees precision and speed. |

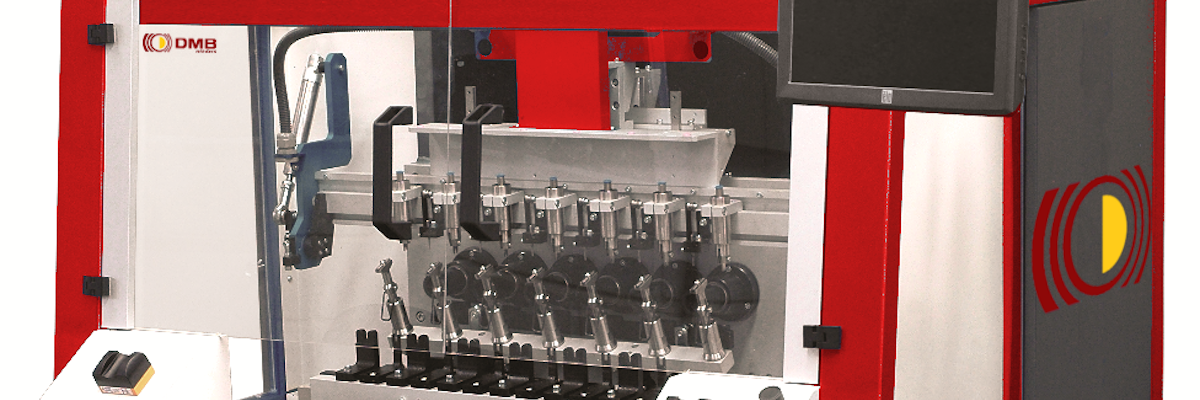

| Hole-Guide Punching Tool |  The interchangeable tool can be in round, square or rectangular form. Built in special steel. A robust eccentric shaft is driven by a servo motor. The interchangeable tool can be in round, square or rectangular form. Built in special steel. A robust eccentric shaft is driven by a servo motor. |

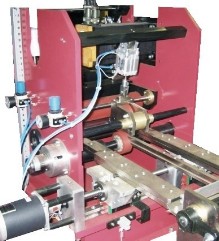

| “V-Notch” Punching Tool |  A sturdy mechanical framework and tungsten carbide knives have been designed to reduce the wasted time in change and adjust of knives. Also, cutting and V positioning are performed servo motors. A sturdy mechanical framework and tungsten carbide knives have been designed to reduce the wasted time in change and adjust of knives. Also, cutting and V positioning are performed servo motors. |

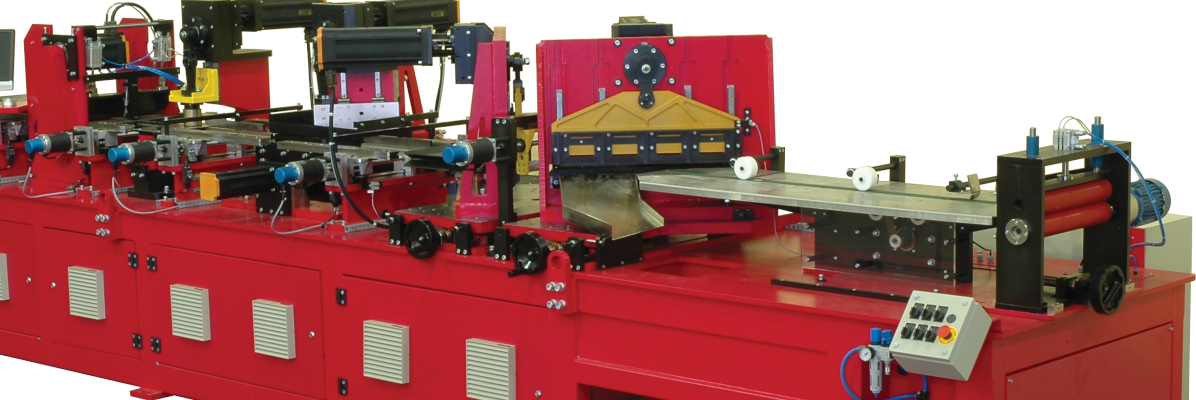

| Shears |  One fixed and other adjustable (45° to 90°) shears have been designed for the use the knives in their four faces and with the possibility of grinding them. One fixed and other adjustable (45° to 90°) shears have been designed for the use the knives in their four faces and with the possibility of grinding them. |

| Stacker |  A simple and efficient stacker. A simple and efficient stacker. |

| HMI | Touch screen with Windows PC |