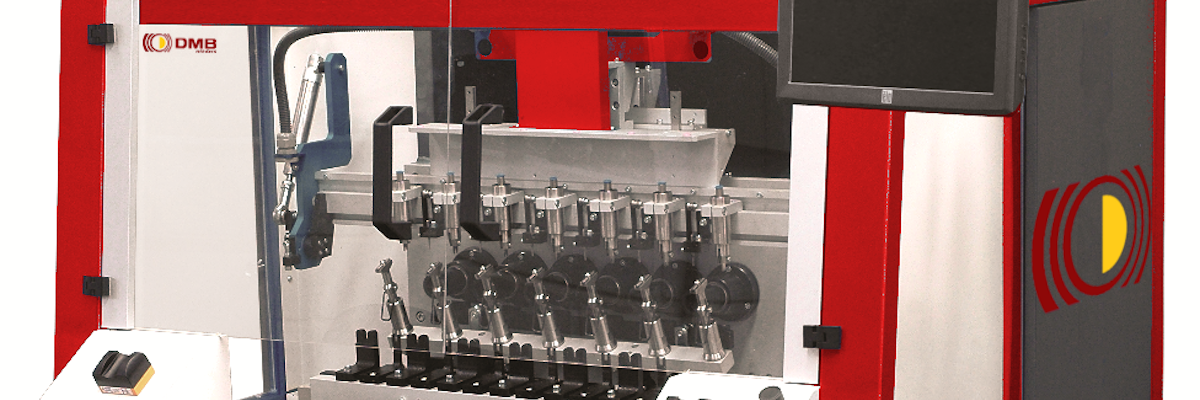

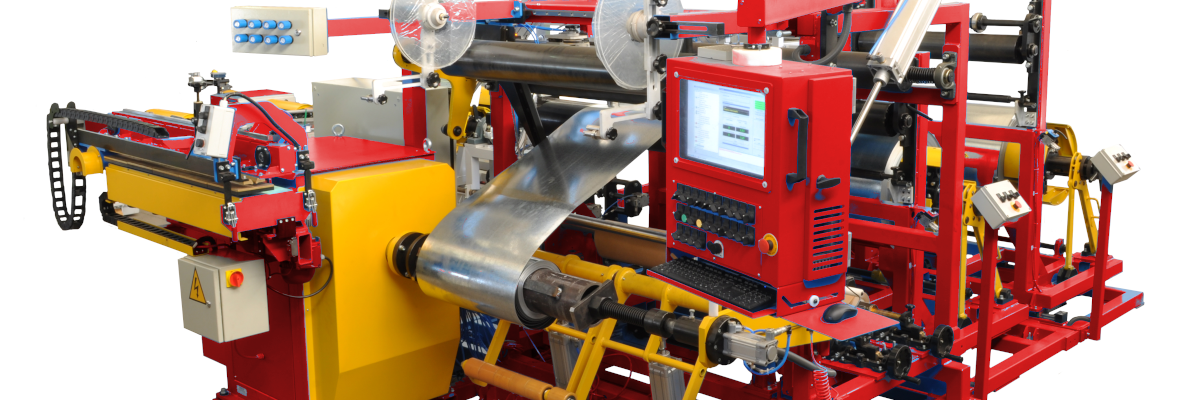

HV, LV or HV+LV winding machine. A heavy duty equipment with state-of-the-art control designed to allow customers a continuous production of complex and simple coils.

| SKU: | L20 |

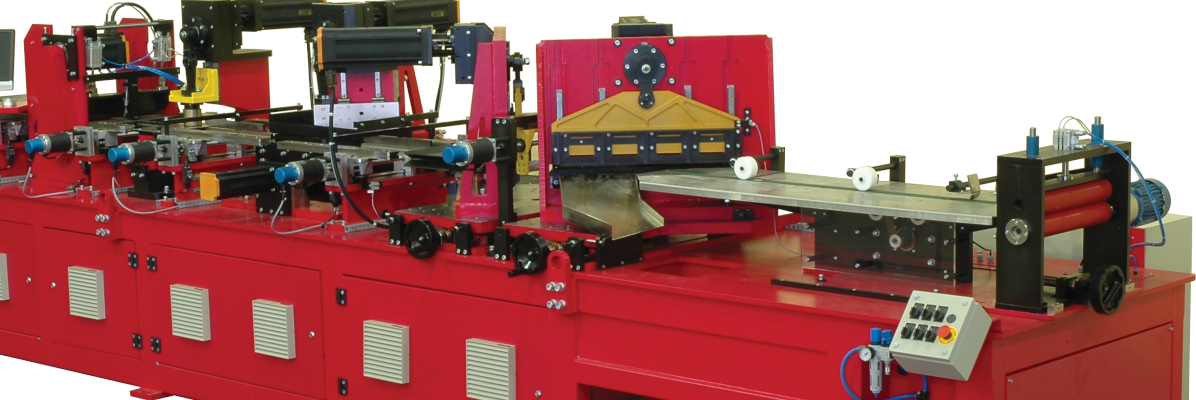

HV, LV or HV+LV coil winding machines for up to 3 coils with multiple wires. This coil winder is a heavy duty equipment with state-of-the-art control designed to allow customers a continuous production of complex or simple coils.

Distribution transformers, measurement transformers, etc…

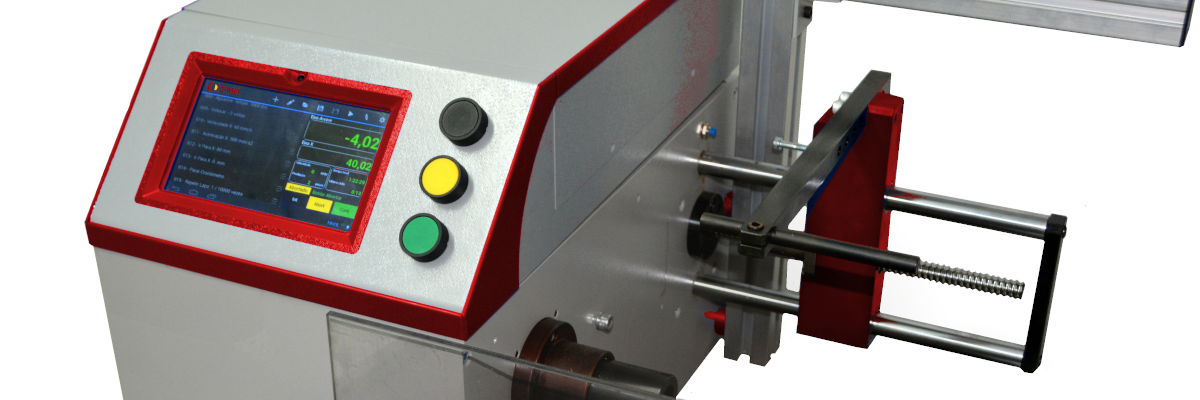

| HMI | Touch screen with Windows PC or Android Tablet |

| Spindle Motor | Induction or Servo Brushless Motor |

| Spindle Max Speed | 120 or 700 rpm |

| Traverse Motor | Stepper Motor or Servo Brushless |

| Traverse Max Speed | 2.75" (70) or 6" (150) in/s (mm/s) |

| Traverse Travel | 27.5" (700) in (mm) |

| Max Coil Diameter | 19.7" (500) in (mm) |

| Round Wire | 2 to 30 AWG |

| Flat Wire | up to 0.157" x 0.39" (4 x10) in (mm) |

| Power Supply | 220 V |

| Weight | 1,433 (650) lbs (Kg) |

| Dimensions | 71" x 39" x 61" (1,800 x 1,000 x 1,550) in (mm) |